GEA

GEA Apollo™ MilkSystem

-

ID # 13683106

- Back ID:13683106

- Book a Demo

- Get Directions

Overview

Overview

Specifications

Videos

Sales People

Contact Information

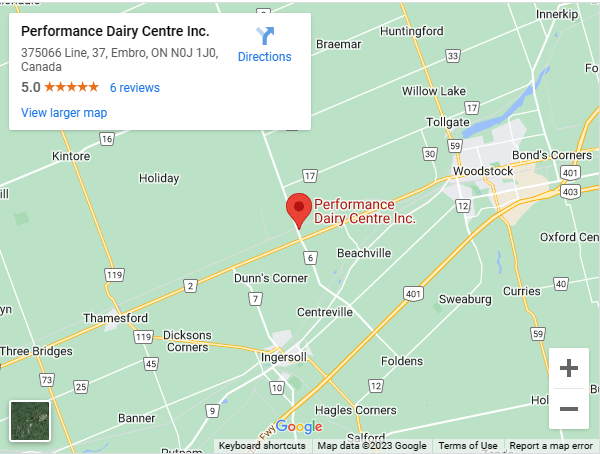

Location

|

This first?of?its?kind product incorporates patented technology to automatically apply post?dip, through the head of the liner at the end of milking, and automatically backflush after detach - facilitating a superior milk harvesting process every time the cow enters the parlor. | |||

| It is a fact that automation can decrease the chance for human error, reduce labor and inefficiencies, and provide more consistent milking procedures. The combination of these benefits, all evident in the revolutionary Apollo™MilkSystem, can improve the milk quality in your herd and positively impact your dairy’s bottom line. | |||

| The Apollo™MilkSystem is an innovative, automated milking unit exclusive to GEA. This first?of?its?kind product incorporates patented technology to automatically apply post?dip, through the head of the liner at the end of milking, and automatically backflush after detach — facilitating a superior milk harvesting process every time the cow enters the parlor. | |||

|

Model

Apollo™ MilkSystem

Sale Type

New

Manufacturer

GEA

Quantity

0

Manufacturer Qty

0

Model

Apollo™ MilkSystem

Sale Type

New

Manufacturer

GEA

Quantity

0

Manufacturer Qty

0